ECE 22.06

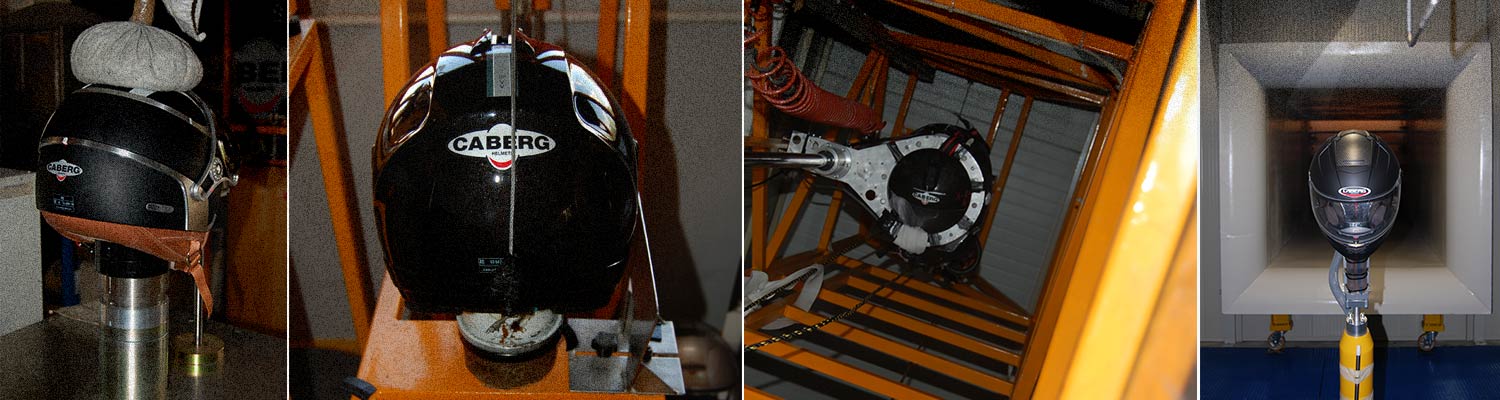

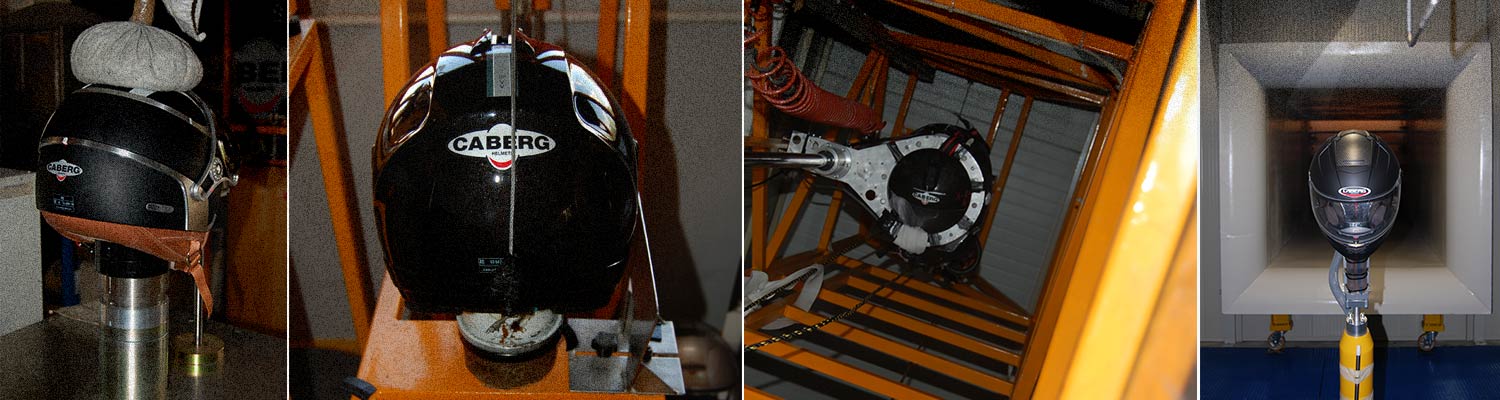

Thanks to a modern certified laboratory Caberg can make internally not only all routine test required by the regulation ECE 22.05 and ECE 22.06, but also additional test to verify new materials and technical solution in order to improve helmets safety. The laboratory is also equipped with instruments to ensure and check components reliability with stress testing and periodical test for durability.

The four basics types test required by International Standards are the shock absorption, rigidity, deformation of the retention system, and the rotation stability.

The "shock absorption test" determines the capacity of an helmet to absorb and dissipate the energy of a blow.

During the test the deceleration of a helmet gauged head form falling free onto an anvil at given speed is measured.

The "rigidity test" measures the maximal and residual deformation of a helmet submitted to lateral or longitudinal compression.

The "retention system test" measures the maximal and residual elongation of the chinstrap of a helmet submitted to dynamic stress at a given energy. The stability measures the roll-of angle of a helmet submitted to a dynamic rotational face.